Latest News

Discover the TGF-Z10P-SI silicone gap filler by HALA Contec – a high-performance, thermally conductive, and soft solution for efficient heat management in electronics, automotive, and medical devices

Explore HALA’s full range of high-performance thermal interface materials in their latest Product Catalogue. From gap fillers to adhesives, discover innovative solutions for every application.

JHC Specialised Solutions is pleased to announce that we have successfully completed our registration on the JOSCAR-AU supplier accreditation register. JOSCAR-AU is an accreditation system for the aerospace, defence and security sectors.

As electronics get faster and more powerful, high-frequency EMI shielding becomes more important than ever. Learn how these dynamics impact data centers and servers and how high-performing gasket options make all the difference.

Selecting the right EMI shielding material for your application can be challenging. The Conductive Elastomer Engineering Handbook published by Parker Chomerics offers detailed technical explanations...

Looking to learn more about thermal gap pads and dispensable gels? Download our new white paper Thermal Interface Materials: Choosing Between Gels and Gap Filler Pads now!

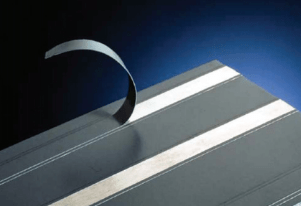

Parker Chomerics CHO-MASK® II is an electrically conductive foil tape layered with a polyester paint masking meant to provide a conductive non-corroding surface on painted metal electronic enclosures.

Are you facing issues with electromagnetic interference (EMI) in your electronic enclosures? Powder-coating can disrupt grounding, but don't worry! Introducing CHO-MASK II EMI masking tapes as a dependable option for preserving a conductive electrical path. CHO-MASK II, with its detailed three-layer design and easy application, creates a conductive and corrosion-resistant surface for powder coating that is compatible with EMI shielding gaskets.

JHC has been advised by Parker Chomerics of an important change to the manufacturing process of CHO-MASK, CHO-FOIL, and CHO-STRAP.

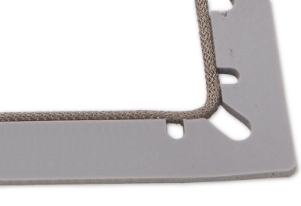

Parker Chomerics SOFT-SHIELD 4850 fabric-over-foam EMI shielding gaskets offer a conductive woven fiber for superior shielding, which can be easily cut to shapes with PSA backing for peel and stick assembly.

This is the second part in a two-part blog post series answering the questions attendees asked during the webinar Selecting a Thermal Gel or Thermal Gap Pad.

This is the first part in a two-part blog post series answering the questions attendees asked during the webinar Selecting a Thermal Gel or Thermal Gap Pad.

Designing the right EMI shielding honeycomb vent for your application can be challenging. Many design variables should be considered when developing an EMI shielding honeycomb vent design.

This Application and Design Guide to EMI Shielding Honeycomb Vents published by Parker Chomerics offers detailed technical specifications and helpful design application assistance.

Discover why the polarity principle is so important to understand when picking a honeycomb air vent panel for EMI shielding.

Honeycomb air vent panels are used to help cool electronics with airflow and while maintaining electromagnetic interference (EM) shielding. The most important factors of honeycomb air vent panels are shielding effectiveness and airflow, which are both directly related to the cell size. Both factors have a large impact on the size, material, and design of the vent panel. While you will need to balance the trade-offs between airflow and EMI shielding needs, you should also ask yourself if air particle filtration is needed as well.

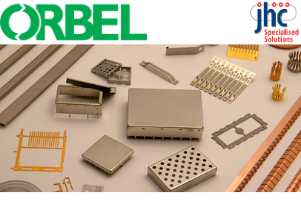

Orbel offers today’s most effective board level shielding, finger-stock gaskets, metalised fabric gaskets, photo-etched precision metal parts, and precision metal stampings.

Areas of specialisation include aerospace, defence, telecommunications, electronics, avionics, energy, medical, power storage, instrumentation, manufacturing, automotive, appliances, and scientific controls

Orbel is excited to announce the latest development in shielding technology, the Groove-Loc™ EMI Shield!

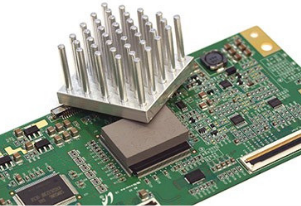

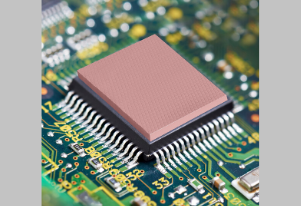

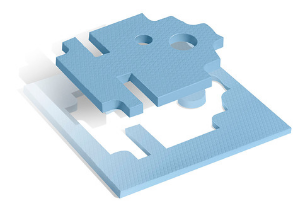

Thermal Interface Materials (TIMs) are considered a crucial part of any efficient thermal management system. Their job is to transfer heat between two or more solid surfaces. Today, thermal interface materials include an array of products, including phase change materials, gap fillers, and thermal grease. Looking to learn more about Thermal Interface Materials? Download this Thermal Interface Materials for Electronics Cooling now.

Over the years, we've taken many questions from customers just like you about the measurement and testing of Parker Comerics' thermal interface materials. How are they used? How are measurements determined? What's the best way to characterize performance?

So we asked our engineers for help answering these questions. Read on to find out their answers.

Comparing different TIMs for a specific application, you can begin with thermal conductivity for general comparisons, but having thermal impedance versus pressure data will be far more accurate to your “real world” conditions.

Single-component, dispensable TIMs such as THERM-A-GAP™ GELs, can cover a variety of gaps and form complex geometries which provide reduced thermal contact resistance, thus reducing the temperature and increasing the efficiency of the application.

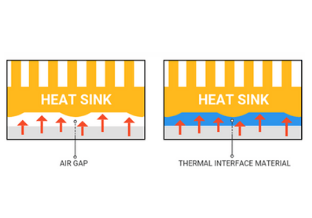

Thermal interface materials are used to eliminate air gaps or voids from adjoining rough or un-even mating surfaces.

Two principal “gap filler” thermal interface materials prevalent on the market today are thermal gels – also known as dispensable gap fillers – and gap filler pads.

So, which one should you select for your application? Here are the top 6 things you need to know

JHC is pleased to announce recognition as the exclusive partner for Orbel within Australia and New Zealand.

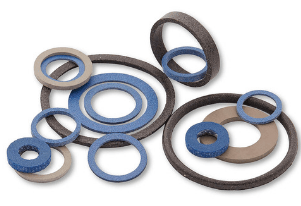

As mentioned in part one of our seal failure blog series, O-ring and seal failures are often due to a combination of failure modes, making root cause difficult to uncover. It's important to gather hardware information, how the seal is installed, application conditions, and how long a seal was in service before starting the failure analysis process. In part 1 of our blog series, we discussed compression set, extrusion and nibbling, and spiral failure. In part 2 of our series, we will review four other common failure modes to familiarize yourself with before diagnosing a potential seal failure in your application.

Seal failures are often due to a combination of failure modes, making root cause difficult to uncover.

These details help bring the overall application into focus and enable us to quickly diagnose and resolve seal failures. In part one of our seal failure blog series, we will discuss the compression set, extrusion, and spiral failure.

Just launched and available to purchase online!! New Copper Tape Handle Covers with antiviral, antibacterial, and fungicidal properties, inactivating 99.98% of the corona viruses after only a few minutes. Suitable for door handles, window handles, handrails and much more…

Hello Copper, Bye-Bye Germs.

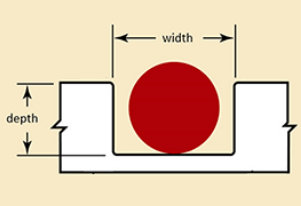

Closure force requirements are an important consideration for sealing applications, and the we’re often asked for guidance as to how to minimise or predict the amount of force it will take to close a properly designed face seal groove.

There are several factors to consider when trying to determine the compressive load. Here are the most important of those considerations.

There are 400+ standard O-ring sizes, so which is the right one for an application? Or maybe you are wondering if one O-ring thickness is better than another. This short article will walk through some of the design considerations for selecting a standard, commercially available O-ring for an application.

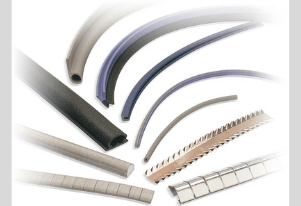

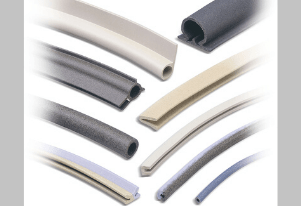

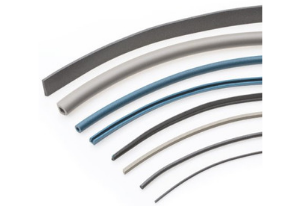

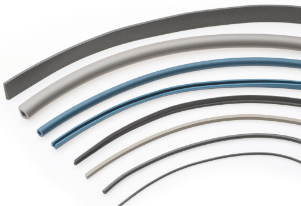

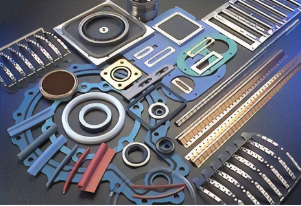

Combination electromagnetic interference (EMI) shielding and weather gaskets, more commonly known as EMI shielded combo strip gaskets, are an excellent choice for a variety of applications that require a resilient, highly conductive sealing solution of knitted wire mesh with the integration of an elastomer for weather sealing. There are five major features to consider for EMI shielded combo strip gaskets.

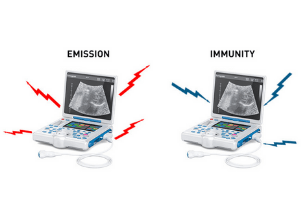

Fundamental design checkpoints of new products generally focus on the designs of mechanical, electrical and software systems. On the whole, EMI/EMC design falls by the wayside for many companies, including preparation for certification testing. When designing a new product, it's best to ask yourself: Has there been consideration in preliminary testing?

A common misconception is that a measurement of DC resistivity can directly predict shielding effectiveness. ... Well, that's because there are many factors that have an impact on shielding effectiveness of a conductive elastomer EMI gasket and the volume resistivity value is only one.

When limiting electromagnetic interference (EMI) in your system, it is very important to shield cables properly since they are often a large contributor of EMI as well as easily affected by neighboring sources. The technology used to shield cables has been around for decades, but the practical application is commonly misunderstood.

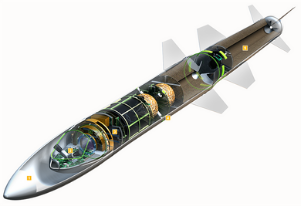

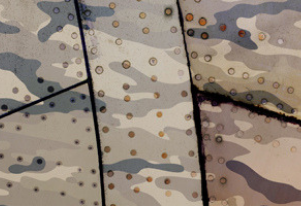

Material selection for military applications requires careful consideration, as there are strict requirements to ensure maximum durability, security and of course performance.

Let's look at three areas of a munitions application -- specifically nose cones, cable shielding, and connectors, as each of these areas exemplify why EMI and environmental shielding are a necessity.

For environmentally-sealed and EMI-shielded electronics devices, there is no better full-system solution than an overmolded or vulcanized cover.

So, what is overmolding/vulcanizing/mold-in-place gasket anyway?

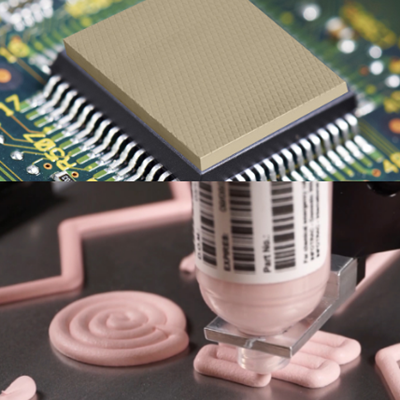

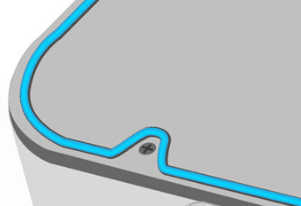

Form-in-place EMI gaskets, also known as FIP EMI gaskets, is a robotically dispensed electromagnetic interference (EMI) shielding solution that is ideal for modern densely populated electronics packaging.

The most important distinction of form-in-place EMI gaskets is that they were developed for applications where inter-compartmental isolation is required to separate signal processing and/or signal generating functions.

Automated form-in-place (FIP) dispensing of EMI shielding gaskets can be ideal for complicated patterns on electronics housings because automation allows for control over the size and shape of the bead. In addition to form-in-place EMI gaskets, thermally conductive gels can also be automatically dispensed, and often span oddly shaped gaps and conform to complex geometries.

Read on for the Top five things to keep in mind when dispensing both form-in-place EMI gaskets and thermal interface materials on die cast aluminium heat sinks

The use of Thermal Interface Materials (TIM) in high volume applications requiring low forces on components has evolved from hand applying greases and thermal pads to the high speed dispensing of 2-part cure in place systems. More recently is the introduction of pre-cured one component gels. Automotive and electronics markets especially require greater throughput with reduced set up, change over, and increased application flexibility. Consumer expectations and warranties necessitate the use of high performance materials able to withstand extreme temperature cycling and shock and vibration environments.

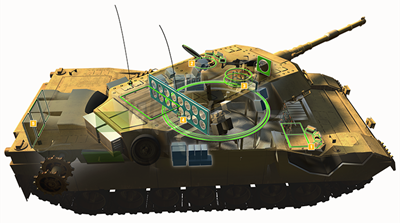

Shielding for electromagnetic interference (EMI) is critical to military electronics systems operating in demanding environments requiring low emitted electronic signatures and protection from electromagnetic radiation. In mobile military applications, EMI shielding must be maintained during storage, transport and operation in a wide variety of demanding and corrosive environments.

Galvanic corrosion is the breakdown of metallic surfaces as a result of the difference in electrical potential of adjacent metals and the presence of an electrolyte. Stated differently, when two dissimilar metals are in contact in a corrosive environment, one of the metals will begin to corrode. So how do we reduce this?

A common question often asked by our customers is the reason why flow rate is reported on datasheets of liquid-dispensed thermal interface materials instead of viscosity. And it’s a fair question; viscosity is a fundamental property of fluids such as thermally conductive pastes. But measuring viscosity, however, is more complicated than meets the eye.

The world of thermal interface materials continues to evolve as the cooling requirements for applications in the automotive, consumer, medical and aerospace markets continue to demand lower prices and higher performance. As each new product generation requires higher power in smaller packages the challenges associated with thermal management become more intense. So which is the best product for your application? Here are the top four thermal interface materials.

Most thermal pads, also known as thermally conductive gap filler pads, thermal gap pads, or thermal gap filler pads, have many different layer materials or carrier substrate options to choose from. It can be confusing which layer is supposed to stay on the product and which layer gets peeled off and removed before application. In fact, it’s one of our customer’s most asked about questions and can cause a lot of confusion on the manufacturing floor.

So, which layer should you peel off and which should stay on the thermal gap pad? Read on to find out.

Finding The Right Elastomer EMI Gasket For You - Parker Chomerics EMI shielding elastomer gaskets are the superior choice for elastomeric seals, corrosion resistance, environmental sealing, and cost effective electronic shielding. Read more to find the right choice for you.

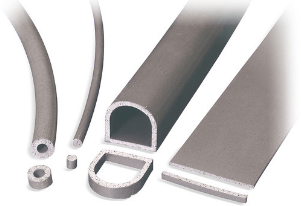

There are two key processes used to create conductive elastomer gaskets: splicing and molding. Do you know the differences? Read more to find out what's best for your application!

There are many electromagnetic interference (EMI) shielding elastomer gasket mounting techniques that offer designers reliable, cost-effective choices in both materials and component assembly. Take a look at the list we've compiled of the seven most common elastomer EMI shielding gasket mounting systems.

Sometimes, applying conductive EMI foil masking tapes can be tricky and quite the hassle. Luckily, we’ve come up with five easy steps to make applying conductive tape easy and worry-free.

When approaching the problem of electromagnetic compatibility (EMC) the electronic design engineer quite often considers it to be a secondary issue that can be dealt with once the device is working and, after all, it can be dealt with by putting a metal box around it!

Designing a custom vent with additional EMI shielding and weather sealing gaskets for a mobile ground radar unit

Pressure sensitive adhesive, more commonly known as PSA, is adhesive which forms a bond when pressure is applied, to join the adhesive with an EMI gasket. As the name "pressure-sensitive" indicates, the degree of bond is influenced by the amount of pressure which is used to apply the adhesive to the surface.

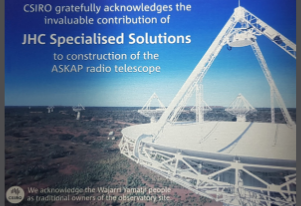

In early 2013 JHC started working closely with CSIRO on a thermal transfer concept to remove heat load from the PAF component of the ASKAP telescope design. With the expertise of our passive thermal transfer solutions partner in Thermacore Europe, a complex heatpipe derived solution evolved to meet CSIRO’s cooling specification. This resulted in an enormous reduction in long term running costs for ASKAP. The last of 36 complete systems was supplied by JHC in mid-2016

Designing a STREAMSHIELD style frame featuring a single layer of 1/8” cell aluminum honeycomb to allow for airflow to be maximised.

Extend the life of your electronics! Download the Thermal Interface Materials For Cooling Electronics Product Guide and discover which thermal interface material is best suited to your application.

There are a variety of thermal pads and gap fillers to choose from -- so many choices that it can become so overwhelming. How can you decide what's best for your application? And how does quality come into play? Read on, we answer these questions and much more.

As the defence industry continues to push the boundaries on advanced electronic systems and state-of-the-art communication devices, the requirements governing these programs must follow suit.

Every design engineer should know that an EMI gasket must be installed between mating flanges to prevent electromagnetic radiation (EMI) from entering or leaving an electronic enclosure. But what if your equipment will be used in humid or tempest environments? How confident are you in your design that corrosion protection will be addressed? Not so much? Then here are our top three design tips for ensuring corrosion resistant EMI protection.

Did you know that up to 80% of conductive coating failures can be directly attributed to inadequate surface preparation? Discover the correct surface preparation needed for a successful conductive paint application now!

JHC have been advised by Parker Chomerics of the discontinuation of their Soft Shield 5000 series gaskets.

JHC is pleased to announce recognition as the exclusive partner for HALA Thermal Interface Materials within Australasia.

Optical Filters has developed Viz-Bond®, a wet bonding system that cures to a gel, to deliver a cost effective, scalable system in which the components are processed at ambient temperature without the use of vacuum, temperature, pressure and need for multiple tooling.

There are many ways to improve the electrical continuity of electronic enclosures and the resultant EMC performance using a variety of electrically conductive gaskets and mechanical fasteners. Such arrangements have the advantage of being clean and easy to use as well as allowing for the equipment to be disassembled and the components replaced. So, ask the question: Is a compound the right solution in this particular case?

A global defense contractor is tasked with developing the next generation of armored land fighting vehicles, each needing to provide first-class protection and surviability, reliability and all-weather performance. All on board electronics need to work efficiently and reliably, but due to the complexity of the operating systems and the volume of electronics inside the vehicle, electromagnetic interference (EMI) is a large issue for the customer.

Parker Chomerics SOFT-SHIELD® 3500 Plated-Fabric Wrapped Foam EMI gasket provides customer with better performance over the life of their project. Parker Chomerics was also able to offer the electronics component manufacturer better service and a larger variety of solutions than their previous supplier.

Due to unanticipated regulatory developments, a raw material used to make CHO-SHIELD 2000 Series coatings has been abruptly discontinued by the manufacturer. This Force Majeure situation has forced Parker to re-formulate the following CHO-SHIELD 2000 series coatings: • CHO-SHIELD 2001 • CHO-SHIELD 2002 • CHO-SHIELD 2003

Parker Chomerics THERM-A-GAP™ GEL 60HF is a single-component, fully cured, dispensable gel with 6.2 W/m-K thermal conductivity. The “HF” in GEL 60HF stands for “High Flow”, indicating that the material is ideal for high volume dispensing applications and high throughput production operations.

Parker Chomerics THERM‐A‐GAP PAD 70TP is a high performance, highly conformable thermally conductive gap filler pad with 7.0 W/m‐K thermal conductivity. “TP” in the product name stands for “Thermal Putty” indicating that, unlike other gap pads, this material is meant for static, one‐time assembly because it will permanently conform to displace air gaps caused by uneven surfaces or rough surface textures.

Parker Chomerics THERM-A-GAP™ PAD 80 is a high performance, thermally conductive gap filler pad with a thermal conductivity of 8.3 W/m-K. It provides superior heat transfer across a range of thicknesses while maintaining low compression forces and conformability between mating surfaces.

You are aware of the need for efficient shielding solutions for signal attenuation in EMI-protected enclosure applications and for electronic devices, from design to production. To meet the design and production requirements for your military and commercial products, you need gaskets and washers in a variety of shapes and sizes. That was a challenging command to fulfill from a lone, trustworthy source. Before now.

Looking for high thermal conductivity, yet ultra-soft thermal gap filler pad? Then you’ll want to take a close look at THERM-A-GAP PAD 60, the next generation of high-performing thermal gap filler pads from Parker Chomerics.

In Chomerics’ recent webinar about electrically conductive sealants and adhesives, viewers learned the difference between an electrically conductive sealant and an electrically conductive adhesive, why you’d choose one over the other, and the design considerations you need to take now. During the Q&A; portion of the webinar, their experts fielded the excellent questions, so we’ve rounded up our eight top favourites.

This deep, technical webinar will dive into cables and connector assemblies. Watch now!